Think of 3D printer file formats, like STL and OBJ, as the "language" your printer understands. In this guide, we will walk you through the common languages of 3D print files.

Common 3D Printing File Formats Explained

Not all 3D printer file formats are created equal. Some are perfect for simple prototypes, while others preserve colors, textures, and even multiple materials. Let’s break down the five most widely used 3D printing file types, their strengths, and their weaknesses—so you can pick the best one for your project.

|

File Type |

Extension |

Differences |

|

STL |

.stl |

Encodes only surface geometry using triangles; no color, texture, or material info; universally supported |

|

OBJ |

.obj |

Stores geometry, color, and texture (with separate files); higher detail than STL |

|

3MF |

.3mf |

XML-based; supports geometry, color, material, textures, and metadata; modern and compact |

|

AMF |

.amf |

XML-based; supports color, material, and scale; less common than 3MF |

|

PLY |

.ply |

Captures shape, color, transparency, and scan data; not universally supported |

How to Choose the Right 3D Printing File Type

To get the best results, the right 3D print file plays a significant role. Here’s a simple guide to help you choose the best format every time.

For Beginners: STL (The Universal Standard)

If you're new to 3D printing, STL is the go-to format. It’s the most widely supported file type, compatible with every slicer and printer, making it perfect for learning the basics. STL files store only basic geometry, so they’re ideal for mechanical parts, functional prototypes, and quick prints where color and texture aren’t important.

However, STL has limitations—it doesn’t support colors, textures, or advanced material properties. Additionally, its simple triangular mesh structure can be inefficient for complex curved surfaces, leading to larger file sizes.

💡 ATTENTION! Since STL files don’t include print settings, you’ll need to manually configure parameters like infill, supports, and layer height in your slicer.

For Multi-Color or Textured Prints: OBJ or 3MF

If your model requires colors, textures, or multiple materials, STL won’t suffice. Instead, consider these alternatives:

-

OBJ (Best for Artistic & Scanned Models) – This format supports UV-mapped textures, making it great for figurines, game assets, and cosplay props. It’s also compatible with 3D painting software like Blender and Substance Painter. However, not all slicers fully support OBJ textures, so double-check compatibility before printing.

-

3MF (Best for Professional Multi-Material Prints) – Designed as a modern replacement for STL, 3MF files can store multi-material data, slicer settings (like supports and infill), and even metadata. This makes them ideal for printers with dual extruders or color mixing capabilities.

For Advanced Features: 3MF or AMF

If your project requires gradient materials, lattice structures, or ultra-smooth curved surfaces, basic formats like STL or OBJ won’t be enough. Instead, consider:

-

3MF (Modern & Versatile) – Beyond multi-material support, 3MF files offer better compression, embedded print settings, and improved mesh accuracy. Most modern slicers (like PrusaSlicer and Cura) fully support 3MF, making it a reliable choice for complex prints.

-

AMF (High Precision, But Rarely Used) – In theory, AMF supports advanced features like curved triangles (for smoother surfaces) and graded material transitions (e.g., flexible-to-rigid). However, very few consumer printers or software fully support AMF, so 3MF is usually the better choice.

For Scanned Models: Depends on the Scanner

If you’re working with 3D scans (from devices like EINSTAR), your scanner will typically export in one of these formats:

-

OBJ → Best for textured scans (common in photogrammetry).

-

STL → Simple, geometry-only scans (easy to edit in CAD software).

-

PLY → Sometimes used for raw point cloud data.

How to Create STL and OBJ Files

Both file types can be generated using most 3D CAD and modeling software:

STL Files:

In most CAD programs (such as SolidWorks, Rhino, Fusion 360, Onshape, AutoCAD, Blender, etc.), you can create an STL file by opening your model and using the export function:

-

File > Export or File > Save As

-

Select "STL (*.stl)" as the file type

-

Adjust export settings if needed (resolution, units, etc.)

-

Save the file to your desired location.

OBJ Files:

Similarly, OBJ files can be created by exporting from the same modeling programs.

-

File > Export

-

Choose "OBJ (*.obj)" as the file type

-

Adjust settings for including textures, materials, or scale

-

Save the file.

How to Convert Between OBJ and STL

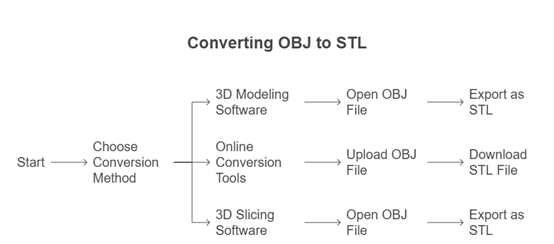

Converting OBJ to STL (and vice versa) is straightforward and can be done using several methods:

Using 3D Modeling Software (e.g. Blender):

-

Open Blender and delete the default cube.

-

Go to File > Import > Wavefront (.obj) and select your OBJ file.

-

Inspect the model for correctness.

-

Go to File > Export > Stl (.stl), set export options (scale, orientation), and save

Other software like MeshLab, Autodesk Fusion 360, FreeCAD, and TinkerCAD also allow you to import OBJ files and export them as STL files.

Using Online Conversion Tools

Platforms like ImageToSTL, AnyConv, and Convert3D allow you to upload an OBJ file and download the converted STL file in seconds.

-

Visit the converter's website.

-

Upload your OBJ file.

-

Wait for the conversion to finish.

-

Download the STL file.

This method is easy and fast, requiring no software installation. However, it may have file size limitations and potential privacy concerns.

Using 3D Slicing Software (e.g. Cura and Other Slicers)

-

Open the OBJ file in the slicer.

-

Export or save as STL.

This method is useful for large files or when you want to prepare the model for printing directly.

When and Why to Convert 3D Model Files

Choosing whether to convert OBJ to STL (or keep OBJ) depends on your project’s needs.

Reasons to Convert OBJ to STL

1. 3D Printing Compatibility

STL is the most widely supported format for 3D printing. While some slicers handle OBJ, STL guarantees compatibility with all printers and slicing software.

If you’re sharing a model for others to print, STL avoids potential issues with unsupported textures or materials.

2. File Size Reduction

STL files only store geometry (triangular meshes), making them smaller and faster to process than OBJ files, which may include textures, colors, and material data.

Useful for large or complex models where slicer performance matters.

3. Simplifying Models for Printing

Since 3D printers only need shape data, converting OBJ to STL removes unnecessary textures/colors, reducing errors in slicing.

Helps avoid corrupted or overly complex meshes that some slicers struggle with.

4. Sharing & Selling Models

Most 3D model marketplaces (Thingiverse, Cults3D, Printables) prefer or require STL uploads to ensure broad usability.

Ensures buyers can print your model without compatibility headaches.

When to Keep OBJ Format

Multi-Color or Textured Prints

If your model requires colors, textures, or materials (e.g., figurines, game assets), OBJ preserves this data. Some advanced printers (like those with dual extruders or full-color capabilities) can use OBJ’s extra information.

Non-Printing Applications

For animation, rendering, or game design, OBJ is better because it retains UV maps and material properties. Software like Blender, Unity, or Unreal Engine relies on OBJ’s additional data for realistic visuals.

Why Not Respond? How to Solve Common 3D Print File Issues

In solving the common printing issues, SHINNING 3D EXModel provides their solutions.

1. Non-Manifold Edges & Holes

Non-manifold edges occur when a mesh has geometry that cannot exist in the real world (e.g., edges shared by more than two faces, holes, or disconnected parts). These issues can prevent successful slicing or printing.

EXModel offers mesh editing features such as filling holes, smoothing, and editing boundaries, which are essential for creating watertight meshes suitable for 3D printing. These tools allow users to easily repair non-manifold edges and close gaps in the mesh, ensuring the model is printable.

2. Large File Sizes

Excessive polygon count leads to large files, slow slicing, and can overwhelm printer memory. Most 3D printers handle models with up to a few million triangles; more is rarely necessary.

The software includes mesh editing tools that make it easy to reduce data size while maintaining accuracy. This means you can simplify your mesh -- reducing polygon count -- without sacrificing th e essential details needed for manufacturing or printing

3. Printer Compatibility Errors

Not all printers or slicers support every file type. STL is universally accepted, while OBJ and 3MF offer advanced features but may not be supported by all hardware/software.

EXModel supports versatile export options, allowing users to save their models in widely used formats such as IGES, STEP, and DXF. This flexibility ensures compatibility with a broad range of 3D printers and CAD systems, helping users avoid printer compatibility errors

Share:

Is EINSTAR 3D Scanner Worth it?