EINSTAR Academy: Your 3D Scanning Guide

3D scanning is becoming a go-to solution across industries—from manufacturing and healthcare to art, education, and research. With its non-contact workflow, high precision, and wide range of applications, it's more accessible than ever.

But with so many scanner types and specs available, choosing the right one can feel overwhelming. That's where EINSTAR Academy comes in. This technical column in the EINSTAR Forum not only breaks down scanning tips & product selection tips, but also provides expert insights to help you navigate the complexities of 3D scanning technology.—so you can scan smarter, faster, and with confidence.

01. What Is 3D Measurement?

3D scanning uses light and sensors to capture an object’s shape, size, and texture, turning real-world items into digital 3D models.

There are two main types of 3D measurement:

- Contact measurement: Requires touching the object. It's very accurate but slow and not ideal for soft or large items. Example: Coordinate Measuring Machines (CMM).

- Non-contact measurement: Uses light to scan without touching. Structured light scanning is fast, precise, and great for scanning complex objects of all sizes.

02. Structured-Light 3D Scanning

How It Works & Light Source Types

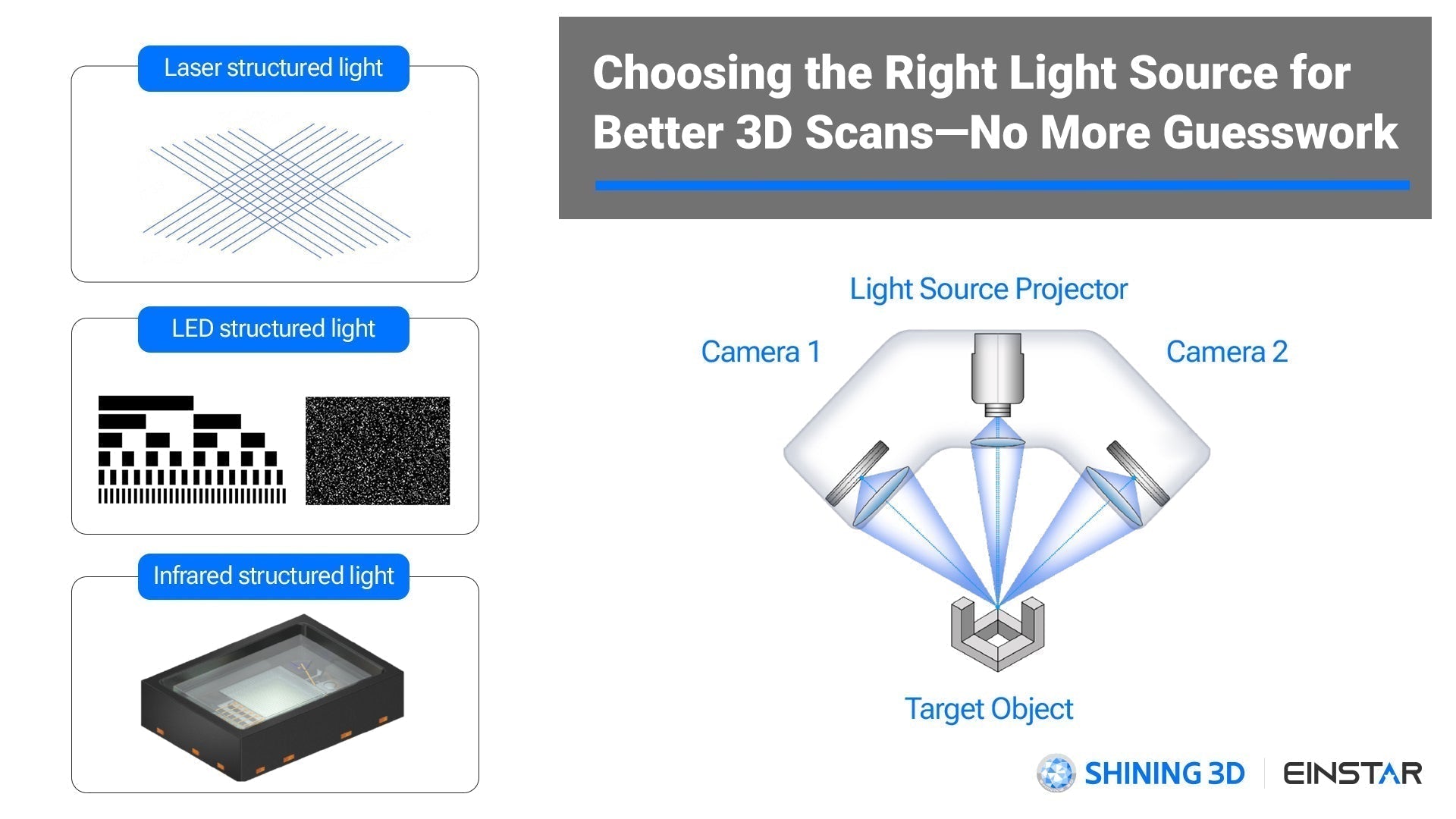

Structured-light 3D scanning is based on optical triangulation. A projector casts a patterned light onto the object’s surface, while cameras capture how the pattern deforms across the shape.

By analyzing these deformations, the system calculates the object’s 3D geometry and generates a point cloud—a digital map of the surface.

This method uses different light sources (e.g., laser, LED, infrared), each suited to specific scanning needs like precision, texture capture, or material adaptability.

🔦 How to Choose the Right Light Source for Structured-Light 3D Scanners

Not all 3D scanners use the same light source—and choosing the right one can dramatically impact your scanning results. Here's a quick guide to the three most common light source technologies and their ideal use cases:

1. Laser Line Scanning

- Metrology-grade accuracy for demanding industrial inspection

- Strong anti-interference performance; works well on black or reflective surfaces

- High scanning efficiency with large scanning range and advanced algorithms (e.g., EinScan RIGIL reaches up to 70 fps)

- Suitable for outdoor environments

- Typically requires markers, though some models support marker-free scanning

Best For:

Large industrial parts, automotive piping, molds, cultural artifacts, and objects that are complex or difficult to touch

Representative: EinScan Rigil

2. White LED Structured Light (Stripe or Speckle Projection)

① Stripe-Based Structured-Light 3D Scanning

Key Features:

- High accuracy and resolution for small to mid-sized precision parts

- Compatible with automated turntables for efficient scanning

- Color cameras support texture capture with excellent color fidelity(example: Transcan C features dual professional color cameras, delivering texture maps up to 12MP for highly realistic color reproduction)

- Equipped with high-resolution industrial lenses for rich surface detail and accurate 3D reconstruction

Best For:

Precision part inspection, product design, digital archiving and display

Representative: Transcan C,EinScan SE2,EinSan SP2

② Speckle-Based Handheld 3D Scanning

Key Features:

- Smooth data acquisition powered by advanced algorithms and stable visual sensors—portable, efficient, and lag-free

- Excellent color reproduction with professional RGB cameras that capture surface texture and color in real time

- Supports multiple alignment modes; rich-feature or textured surfaces can be scanned without markers

Best For:

Art and culture, medical, orthotics & prosthetics,education and researchand other 3D design.

Representative: EinScan Medixa

3. Infrared VCSEL

3. Infrared VCSEL

Infrared VCSEL lasers are invisible light sources. High-quality VCSEL infrared laser projectors project structured light with specific features onto the object being scanned (the light is invisible to the human eye). Special infrared cameras are used to capture the reflected light and obtain the object's three-dimensional spatial information. Finally, software processes this information to generate images and reconstruct a 3D point cloud model.

Key Features:

- Ideal for human body scanning and educational use

- Eye-safe, soft illumination that’s comfortable for subjects

- Supports handheld scanning; lightweight and easy to operate

- Performs well on black or shiny surfaces

Best For:

Human modeling, education and research, rapid prototyping

Representative: EINSTAR,EINSTAR VEGA

These light source modes represent the majority of 3D scanner currently available on the market. Each approach—whether fringe-based, speckle-based, or laser line scanning—offers distinct advantages and limitations depending on the application. From high-precision industrial inspection to full-color human body digitization, users can select the most suitable solution based on their specific scanning needs, object characteristics, and working environment.

If you need any help with scanner selection, Welcome to www.einstar.com for free consultation! There are many professionals there to answer your questions about model selection!

Share:

Want Faster 3D Scanning? These 4 Factors Could Save You Hours

How to 3D Scan a Car with EinScan Rigil (Automotive Parts as Well)