1.Was ist Reverse Engineering?

Beim Reverse Engineering werden Konstruktionsinformationen aus einem bestehenden Teil oder System extrahiert und digital in ein bearbeitbares 3D-Modell rekonstruiert. Reverse Engineering wird häufig in der Automobilindustrie, im Baumaschinenbau, in der Schwerindustrie und anderen Bereichen eingesetzt, um Ingenieuren und Herstellern zu helfen:

-

Wiederherstellen veralteter oder fehlender Teile

-

Analysieren Sie konkurrierende Designs, um Ihre eigenen Produkte zu optimieren

-

Reparieren oder ersetzen Sie verschlissene Teile

-

Maßgeschneidertes Zubehör und individuelle Modifikationen

Die traditionelle Methode basiert auf manuellen Messungen, die wenig effizient sind, große Fehler verursachen und bei komplexen Oberflächen schwierig zu handhaben sind. Die moderne 3D-Scantechnologie hat diesen Prozess revolutioniert.

2.Manueller vs. 3D-Scan

|

Handbuch |

3D-Scannen |

|

|

Effizienz |

❌Ineffizient, zeitaufwendig |

✅Schnelle Erfassung der vollständigen Geometrie |

|

Genauigkeit |

❌Fehleranfällig, begrenzte Punkte |

✅Hohe Präzision, kleiner Fehler |

|

Anpassungsfähigkeit |

❌Schwierig zu handhabende komplexe Oberflächen |

✅Erfassen Sie Freiformformen und Details |

Mithilfe leistungsstarker 3D-Scanner wie EinScan RIGIL und EINSTAR VEGA können Ingenieure schnell Oberflächendaten erfassen und hochauflösende digitale Modelle erstellen und so eine solide Grundlage für CAD-Reverse-Engineering schaffen.

3. Reverse-Engineering-Prozess (nehmen Sie EinScan RIGIL & EINSTAR VEGA als Beispiel)

Schritt 1: Scannen Sie das Objekt

Verwenden Sie RIGIL oder VEGA, um das Zielteil zu scannen und die hochpräzise Datenerfassung in wenigen Minuten abzuschließen.

Schritt 2: Hochwertiges Netz generieren

Punktwolkendaten werden in ein geschlossenes Netz (STL) umgewandelt, das direkt auf dem Gerät bereinigt und optimiert werden kann.

Schritt 3: Vom Netz zum CAD-Modell

EXModel-Software über einen Schlüssel, um das Netz in ein bearbeitbares parametrisches CAD-Modell zu konvertieren.

Schritt 4: Analyse und Herstellung

Das fertige CAD-Modell kann verwendet werden:

-

✔Größenoptimierung und Leistungsverbesserung

-

✔CAE-Analyse (Spannung, Flüssigkeit usw.)

-

✔Ausgabe von CAD-Dateien für CNC-Bearbeitung, Spritzguss oder 3D-Druck

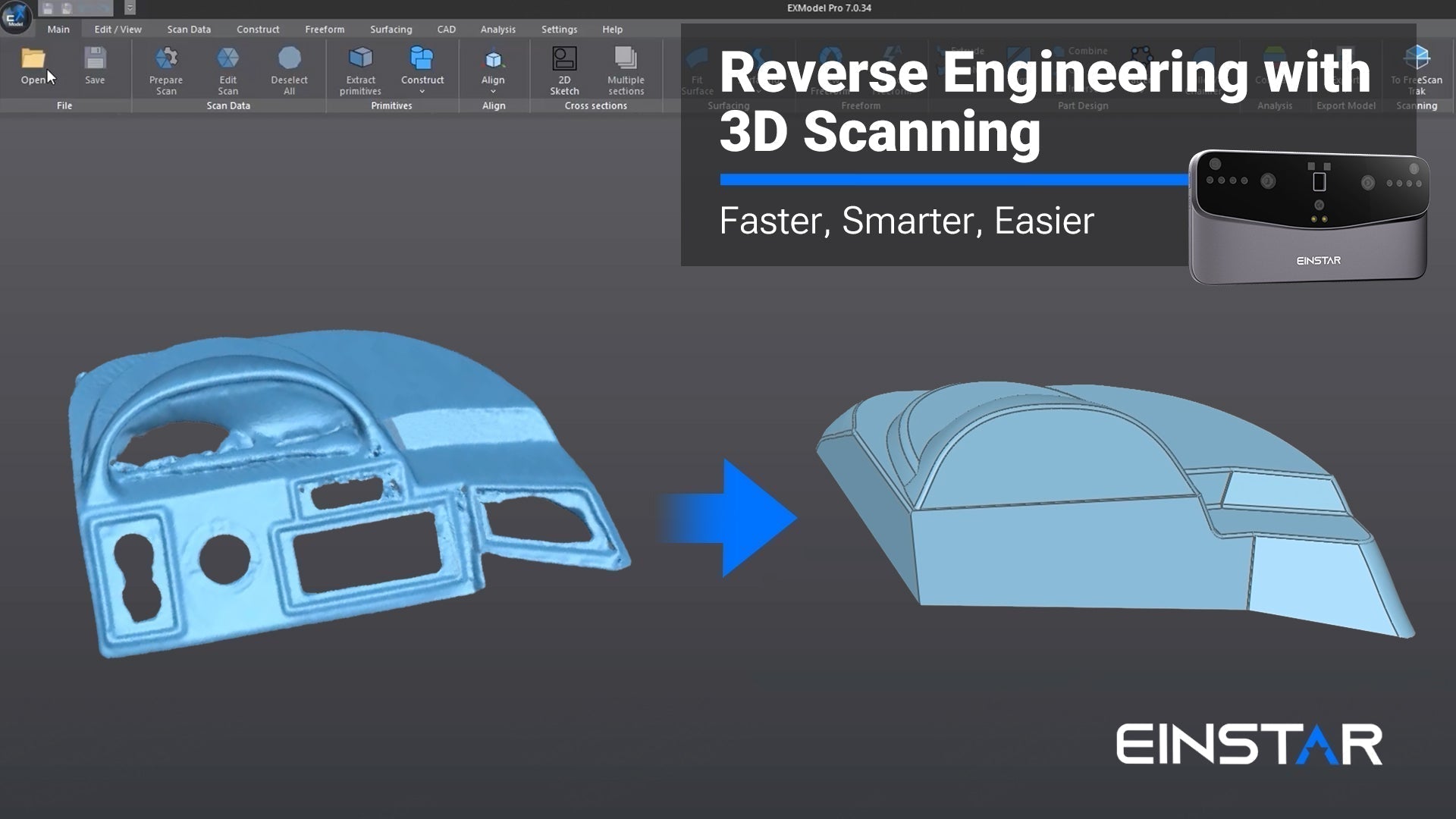

4.Empfohlene Software: EXModel

EXModel ist ein wichtiges Tool zur Verbindung von 3D-Scanning und CAD-Modellierung mit den folgenden Vorteilen:

-

Scandaten-Import mit einem Klick

-

Automatische Generierung parametrischer CAD-Modelle

-

Kompatibel mit gängigen CAD-Plattformen

-

Unterstützung für die Modellierung und Modifikation komplexer Strukturen

Zu den üblichen Anwendungen zählen: individuelle Anpassung von Autostoßstangen, Design von Yachtteilen, Formenrestaurierung, Entwicklung elektronischer Produkte usw.

5. Anwendungsfälle

🚑Modifikation des Krankenwagens

Blue Sky Rescue verwendet VEGA zum Scannen der Innenstruktur, um die Layoutoptimierung und Geräteintegration schnell abzuschließen.

🛥Yacht-Konsolenanpassung

Edward verwendet VEGA, um Yachten im Außenbereich zu scannen und so die Ausstattung und Produktivität zu verbessern.

6. Fazit

Angesichts der steigenden Anforderungen an Geschwindigkeit und Genauigkeit in der Fertigungsindustrie ist 3D-Scannen zu einem unverzichtbaren Werkzeug für das Reverse Engineering geworden. Mit EinScan RIGIL und EINSTAR VEGA können Ingenieure Folgendes erreichen:

-

Kostensenkung

-

Umgang mit komplexen Strukturen

-

Beschleunigen Sie den Design- und Herstellungsprozess

Share:

EXModel-Tutorials

Die Genauigkeit von 3D-Scannern: Was Sie wirklich wissen müssen